YOZONE Prodcues Quality Extruded Tubing

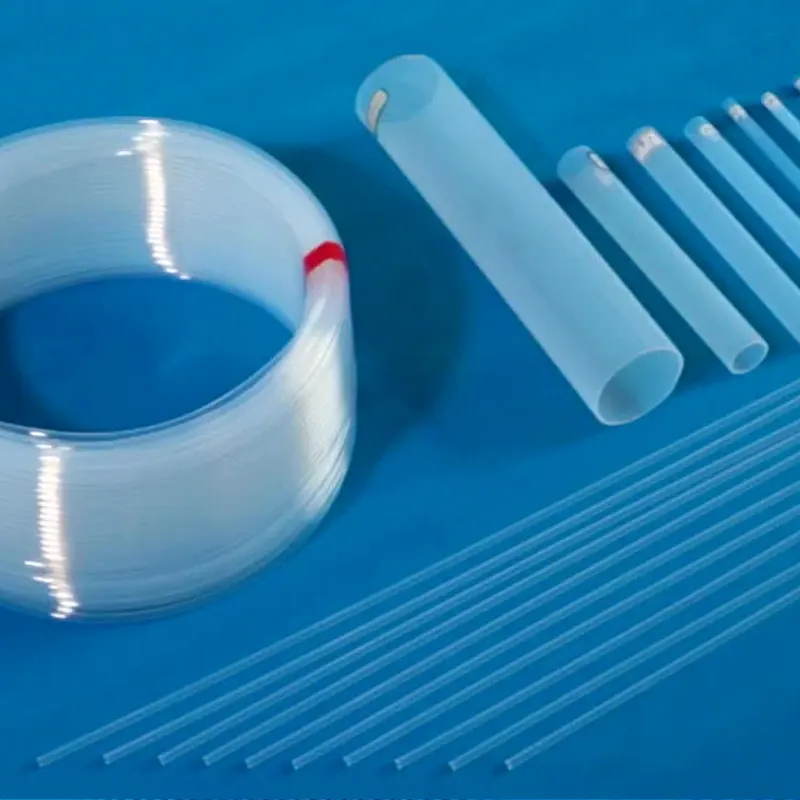

Компания YOZONE Technology предлагает следующие ключевые решения для продуктов PTFE, FEP, PFA и PEEK. Итак, сегодня мы познакомим вас с нашими высококачественными экструдированными трубами:

Отжимные трубы YOZONE являются многофункциональным продуктом, который широко используется в различных отраслях промышленности. Это непрерывный материал, который, заставляя его формироваться через форму, образует полый цилиндр.

Benefits of Extruded Tubing

- Dimensional Accuracy: Extruded tubing offers precise dimensional tolerances. This precision is crucial for applications where tight fits or specific dimensions are required.

- Uniform Wall Thickness: The extrusion process ensures uniform wall thickness. This uniformity is especially important for applications involving fluid or gas flow.

- Smooth Surface Finish: Extruded tubing has a smooth interior and exterior surface. The smooth surface also enhances the aesthetic appeal of the tubing and facilitates cleaning and maintenance.

- Material Versatility: Extruded tubing can be produced from a wide range of materials, including metals, plastics, and rubber.

Applications of Extruded Tubing

- Automotive Industry: Extruded tubing is used in fuel lines, brake lines, coolant lines, and various other fluid transfer systems in vehicles.

- Medical Industry: Extruded tubing is employed in medical devices such as catheters, IV tubing, and surgical instruments.

- Electrical Industry: Extruded tubing serves as insulation for electrical wires and cables.

- Plumbing and Construction: Extruded tubing is used in plumbing systems for water supply, drainage, and irrigation.

- Aerospace Industry: Extruded tubing is used in aircraft components, such as fuel lines, hydraulic lines, and structural supports.

- Food and Beverage Industry: Extruded tubing is employed in food processing and packaging applications, transporting liquids and powders efficiently.

- Consumer Products: Extruded tubing finds applications in various consumer products, including straws, toothpaste tubes, and cosmetic containers.

How YOZONE Promise The Quality of Products?

Чтобы соответствовать спецификациям ASTM, GB / T и ISO, YOZONE Technology использует стандартные испытательные машины для контроля качества продукции, такие как тестер плотности, измерительный прибор давления при взрыве, измерительный стержень, микрометр толщины стенки, измерительная машина для растяжения, измерительный прибор для всасывания воды и т. Д.

Технологические методы следующие:

1. Сырьевые материалы

2. Форма

3. Выдавливание

4. Спекание

5. Испытания в процессе производства

6. Изготовительные испытания

7. Упаковка

8. Транспорт

Why Do Foreign Customers Choose YOZONE?

- Our company holds prestigious certifications including ISO 9001 and verifications from UPS Class Vi, FDA, ROHS, REACH, and CE

- Stay informed with our weekly status reports, providing you with comprehensive updates on all aspects under your control.

- Enjoy the benefits of our OEM/ODM service, where we offer customized label packaging tailored to your specific requirements.

- With a network of seven factories across China, we guarantee a monthly production output of 25 million meters of top-notch products.

- Experience seamless and professional communication with our team of senior technical engineers, available 24/7 to address your queries and concerns.

- Rely on our extensive expertise in the PTFE tube industry, with over 15 years of experience delivering exceptional solutions to our valued customers.